Affiliate Disclaimer: This post may contain affiliate links, meaning we get a commission if you decide to make a purchase through our links, at no extra cost to you.

What Does a Pressure Washer Do?

Pressure washers have become our trusty allies in the battle against stubborn dirt. Pressure washing is utilized in various settings, from home courtyards to industrial facilities. It ensures that everything remains spotless.

Whenever a stubborn stain needs to be removed quickly, a pressure washer is the go-to tool for delivering swift and effective cleaning.

Pressure washers are great tools for cleaning, but they can be tricky to use. One common issue is when the water stream starts to stutter instead of flowing smoothly. This can be frustrating and slow down your cleaning progress.

It’s important to know that this is called pulsing or surging, a normal phenomenon that can happen with pressure washers.

What Does it Mean by Pulsing Pressure Washer?

A pulsing or surging pressure washer experiences fluctuations in water pressure. This manifests as irregular bursts of high and low pressure during operation. These fluctuations can stem from various issues such as air leaks, pump problems, or blockages in the system.

Understanding Pressure Washer Pulsation

If you’re using a pressure washer and notice that the water flow is irregular like it’s pulsating when you pull the trigger, that’s not a good sign. Instead of a steady stream of water, you’ll notice a jumpy and uneven spray, which can be frustrating and time-consuming.

The cleaning performance of your pressure washer can be severely reduced if your pressure washer is pulsating.

This pulsation means there’s an issue with the washer, and the water isn’t flowing as well as it should. It’s important to identify the cause of the pulsation, as it could be a small fix or a sign of something wrong with the washer’s internal components. The first step to fixing the issue is understanding what’s causing it.

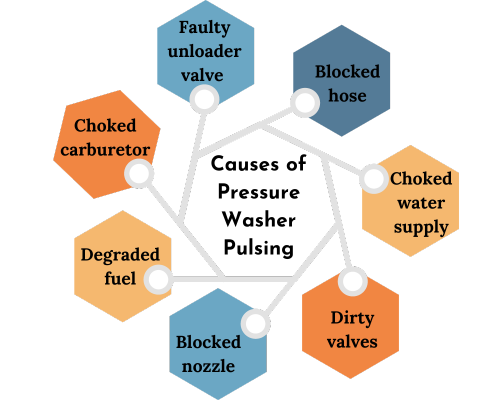

Causes of Pressure Washer Pulsating

Unloader Valve Issues

An unloader valve directs water flow in the washer. If it’s acting up, your water pressure dances. One minute, it’s strong; next, it’s weak. This yo-yo effect is because your valve isn’t doing its job right.

Starving the Pump of Water

A water-starved pump can also cause pulsation. If your washer isn’t getting enough water, it can’t put out enough. Hence, the pressure jumps, just like someone gasping for air.

Moreover, the air in the pump can cause irreparable damage. The solution is simple enough – ensure a steady, generous water flow.

Head Washout

Picture a damaged pump head. It can’t hold water pressure like it should. The result? Pulsation. Look for signs of wear and tear on the pump head. If you see damage, consider getting it repaired or replaced.

Clogged Nozzles

Nozzles can get blocked by dirt or debris. Clogged nozzles can’t let water out smoothly, causing pressure jumps. Cleaning these nozzles can restore your machine’s natural rhythm.

Blocked or a Leaked Hose

Your washer hoses are like veins, supplying water for the washer to pump out. If these are blocked, your washer pulses with irregular water flow, much like a traffic jam causing hasty starts and abrupt stops. The answer? Check your hoses; they may need a cleanup or a replacement. Also, ensure that the water inlet valve is fully open.

Alternatively, the water inlet garden hose supplying water to your pressure washer may have a leak that is large enough to cause a significant pressure drop. This may result in your pressure washer starving of water.

Dirty Water Valves Playing Spoilsport

Water valves control the water’s path, ensuring it goes where needed. But if they have dirt and debris, they add to the water pressure’s drama, causing its performance to falter, just like a mismanaged navigation system leading you to random stops and starts.

A thorough cleaning of dirty inlet or discharge valves can make them functional again. Using an inlet filter like the one below can help reduce this problem.

M MINGLE Pressure Washer Inlet Filter

- Connects to pressure washer inlet

- Prevents blockage

- Protects pressure washer parts

- 3/4 inch GHT male & female thread

Hard Water Residues

Have you ever heard of hard water residues? These are mineral deposits left by hard water. Over time, they clog up the device, hampering the smooth water flow. The effect? Yes, you guessed it – pulsation.

Think of it like cholesterol blocking your arteries, causing irregular heartbeats. A regular cleanup can save you from these invisible enemies.

Restricted Carburetor

A restricted carburetor can cause a gas pressure washer to surge at idle. The carburetor is responsible for mixing air and fuel in the right proportion for combustion.

Over time, dirt and debris can accumulate in the carburetor, restricting the flow of fuel and causing surging.

Degraded Fuel

Degraded fuel can cause a gas pressure washer to surge at idle. Over time, gasoline can lose its volatility and become less effective, resulting in poor engine performance and surging.

Pressure Washer Surging at Idle VS Running

Pressure Washer Surging at Idle

Pressure washer surging when idle? Know the common causes.

- Jammed unloader valve

- Blocked carburetor

- Dirty air filter

These issues can make pulsations noticeable during idle. Surprisingly, these factors may not significantly cause pulsations when the washer is running.

Pressure Washer Running Smooth

If your pressure washer operates smoothly when the washer is running it is mainly because:

- The flow of water can counteract inconsistencies.

- Blocked valves or filters are less noticeable.

Running state helps mask mechanical issues.

The Impact of Water Flow

Why water flow is key?

- Affects pulsations in running vs idle states.

- The idle state exposes inconsistencies in the engine.

- Running state hides issues due to high pressure.

Understanding the difference helps troubleshoot effectively.

How to Troubleshoot A Hiccupping Pressure Washer!

Here are some of the steps you can take to fix the surging pressure washer.

How to Clear a Blocked Nozzle

You may need a nozzle cleaning kit for this step. Here is everything you need to do:

- Disconnect the power source before you start.

- Start the process by turning off your inlet water.

- Remove the spray nozzle from your washer.

- Look inside the nozzle. Can you spot any foreign objects in there? If yes, fetch a pin or a small wire.

- Use your chosen tool to dislodge any debris you find gently. Be gentle! You don’t want to damage your nozzle.

- Once done, reconnect the nozzle to your washer.

Re-start your water supply, then turn on the pressure washer. What’s the water stream like now? Smooth flowing? Great! You nailed it. If it’s still jumpy, move on to the next stage of the troubleshooting guide.

How to Fix a Restricted Carburetor

- Turn off the pressure washer and disconnect the spark plug wire for safety.

- Locate the carburetor, which is usually found near the engine.

- Remove the carburetor by following the instructions provided in your pressure washer’s manual.

- Disassemble the carburetor and clean all its components using a carburetor cleaner or a mixture of warm water and mild detergent. Use a soft brush or cloth to remove any debris or dirt.

- Reassemble the carburetor and reinstall it on the pressure washer.

- Reconnect the spark plug wire and start the pressure washer to test if the surging issue has been resolved.

How to Fix Degraded Fuel

- Turn off the pressure washer and disconnect the spark plug wire for safety.

- Drain the old fuel from the pressure washer’s fuel tank.

- Clean the fuel tank using a fuel tank cleaner or a mixture of warm water and mild detergent. Rinse the tank thoroughly and allow it to dry completely.

- Refill the fuel tank with fresh gasoline, preferably with a fuel stabilizer to prevent future degradation.

- Reconnect the spark plug wire and start the pressure washer to test if the surging issue has been resolved.

To Replace or Not to Replace? Figuring Out if Your Pump’s Time Is Up

If your pump is causing the problem, you might need a new one. But how do you know for sure? Look for the following tell-tale signs your pump is in its endgame:

- See any water escaping from your pump? That’s a sure sign of trouble.

- Does your washer shake more than a dancing washing machine? Yours could have a pump problem.

- Despite good water flow and unclogged nozzles, is your water pressure more kitten than a lion?

If these signs seem familiar, your pump likely needs to be replaced.

How to Identify and Address Unloader Valve Problems

Think of your unloader valve as a traffic cop. You get a traffic jam in your washer when it’s not working right. So, let’s get that valve in order:

- Always start by turning the pressure washer off.

- Extract the unloader valve.

- Examine the valve’s spring. If it seems worn or broken, you need a new one.

- Now, look at the valve itself. Does it show signs of wear and tear? If yes, go ahead and replace it.

See if that fixes the problem. Well done! If not, you’ve done all you can. Now, it might be time to call in the pros.

Keep Calm and Troubleshoot

Are you feeling the pressure from your pulsating pressure washer? Breathe. Dealing with pressure washer problems is not as dire as it seems.

Take Heart, You’ve Got This!

A few simple checks can often provide a quick resolution or a temporary fix:

- Check Water Supply: Is your water source fully turned on? A half-open tap can cause fluctuating pressure.

- Inspect Hose Kinks: Is the hose kinked? Straighten it out to ensure a consistent water flow.

- Secure Connections: Are all connections tight? Loose fittings can lead to air getting into the system, causing pulsations.

- Water Temperature: Is your water too hot or too cold? Some washers have optimal operating temperatures. Check yours and adjust accordingly.

- Consult the User Manual: Most user manuals contain troubleshooting guides that may help fix the problem.

Pro Tips for Preventing Pressure Washer Pulsing

Want to avoid the heart-thumping sensation of a pulsating pressure washer? It’s easier than you think with some routine maintenance.

Regular Maintenance is Your Ticket to Smooth Operations

Let’s start with the basics. Keep your pressure washer in peak shape. It’s easy.

- Change the oil in your pressure washer regularly

- Clean your machine after each use.

- Winterize and store your pressure washer away from humid areas when not used for long periods.

Stick to these simple pressure washer maintenance routines. Your washer will thank you for it.

Clean & Consistent Water Supply

Maintain your water flow too. Ensure the source is clean and consistent. Blockages or dirt can disrupt the flow. The result? Those pesky pulsations. So, double-check your water source before you switch it on!

Nozzle Care: The Secret Ingredient for Smooth Flow

The nozzle needs care as well. Clean it after each use. Inspect it for any blockages. Why? Nozzles are the gateway for water to flow out. Keep it obstruction-free and maintain that steady stream.

Wrap Up

Great! Now, you have learned how to prevent your pressure washer from malfunctioning. It’s a simple process. Have you been maintaining your washer by cleaning and oiling it regularly? This helps a lot.

Additionally, ensure that you are using clean water. It’s another step towards success. Lastly, take good care of your nozzle: keep it clean to maintain a steady water flow.

Adopt these tips as your own, and you’ll enjoy a smoothly running pressure washer at your fingertips, ready to work for you.

Frequently Asked Questions (FAQs)

What could cause a pressure washer pump to pulsate at high rpm?

A: High RPM pulsation in a pressure washer pump is typically related to an inadequate water supply, air entrainment in the pump, or a malfunctioning unloader valve. Ensure the water supply is sufficient and check for clogged filters or hoses that might introduce air into the system. Moreover, inspect the unloader valve for proper function and adjustment.

Can a faulty nozzle contribute to a pressure washer’s pulsing issue?

A: Absolutely. A worn-out, partially clogged, or incorrect nozzle size can cause pulsing by disrupting the flow and pressure balance within the system. It’s critical to use nozzles that match the specifications of your pressure washer and to keep them clean and in good condition.

How does an imbalanced water supply affect pressure washer performance?

A: An imbalanced water supply can significantly affect performance by causing fluctuations in water pressure and flow rate, leading to pulsing. A consistent, adequate water supply according to the pressure washer’s specifications is vital for stable operation. Any deviation can cause pulsation due to the pump struggling to maintain consistent pressure.

Is it possible for electrical issues to cause pulsation in electric pressure washers?

A: Yes, electrical issues, such as insufficient power supply, voltage fluctuations, or a malfunctioning motor, can lead to pulsation in electric pressure washers. Ensuring a stable power supply and routine maintenance checks on the electrical components can mitigate this issue.

Can prolonged inactivity lead to pulsing problems in pressure washers?

A: Prolonged inactivity can contribute to pulsing problems due to the potential for seals to dry out, corrosion to develop in critical components, or sediments to accumulate within the system. Regularly running the pressure washer, even during periods of non-use, can help maintain the integrity of its components.

How does the unloader valve configuration affect pressure washer pulsing?

A: The unloader valve plays a crucial role in regulating pressure within the pressure washer. Incorrect adjustment or failure of this valve can cause pulsing by not properly redirecting water flow when the trigger is released, or by failing to maintain consistent pressure during operation. Careful adjustment according to manufacturer specifications is essential.

What role does pump type play in pressure washer pulsing issues?

A: Pump type can influence the likelihood and causes of pulsing. For example, axial cam pumps are less complex but might be prone to pulsation due to wear or imbalance more quickly than triplex pumps, which are designed for durability and consistent performance. Understanding the characteristics of your pump type can guide troubleshooting efforts.

Can adhesives or sealants used in pressure washer assembly contribute to pulsing?

A: If adhesives or sealants block water passages or are incorrectly applied during maintenance or repair, they can contribute to pulsing by restricting water flow or causing leaks within the system. It’s important to follow the manufacturer’s guidelines for maintenance and repair to avoid such issues.

How does hose length and diameter affect pulsing in pressure washers?

A: Using a hose that is significantly longer than recommended or with a diameter not suited to the pressure washer’s specifications can cause pulsing. This is due to the increased resistance and the time it takes for water to travel through the length of the hose, affecting the pressure and flow rate consistency.